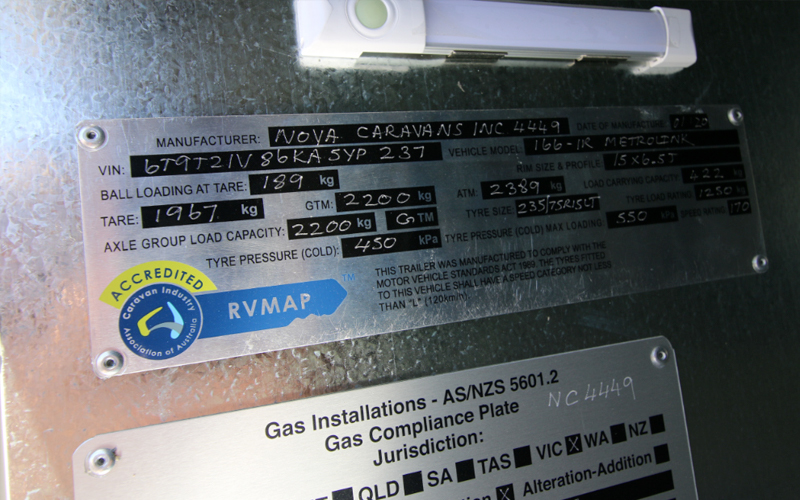

A caravan’s tyre placard, which is usually incorporated within the van’s compliance plate, is an important part of a caravan or camper trailer. The intent of affixing a tyre placard to a vehicle is to provide an assurance from the manufacturer to a potential buyer that the selected tyre size and load rating, along with the recommended tyre inflation pressures, have been professionally determined, so as to provide the optimum caravan handling and stability performance, at both the empty and the fully-loaded conditions.

UNDERSTANDING THE PLACARD

The tyre placard must show at least the following information:

• Caravan manufacturer’s recommended tyre size;

• Tyre load rating

• Tyre speed rating; and

• Cold inflation pressures

The tyre placard must also contain the following statement:

“The tyres fitted to this vehicle shall have a speed category not less than ‘L’ (120km/h).”

If the recommended maximum vehicle operating speed is less than 120km/h, it should say,

“The tyres fitted to this vehicle shall have a speed category at least equal to the recommended maximum vehicle operating speed, ‘…’ km/h.”

In this case, ‘…’ is the vehicle manufacturer’s recommended maximum vehicle operating speed. It is not permitted to state any specific tyre manufacturer’s name or brand. The tyre load rating must be stated in kilograms and the tyre inflation pressures must be stated in kPa (not psi).

It is essential that caravan buyers fully understand all of the information that is provided by the manufacturer on the tyre placard, before they accept the caravan, in order to avoid possible problems in the future. If you have any questions about any items on the tyre placard, it is important to have the dealer provide a credible explanation.

You can also ask a tyre specialist if you have any questions regarding the tyres fitted to your van, or if they can recommend a better tyre. All relevant tyre and permitted wheel specifications are listed in the Tyre and Rim Association of Australia’s Standards Manual – visit www.tyreandrim.org.au

TYRE LOADS

For load-sharing suspension systems, the maximum legal individual tyre load equals the GTM rating divided by the number of tyres fitted to the van. The individual tyre load, when the van is empty, equals the Tare mass minus the empty ball loading divided by the number of tyres fitted to the van.

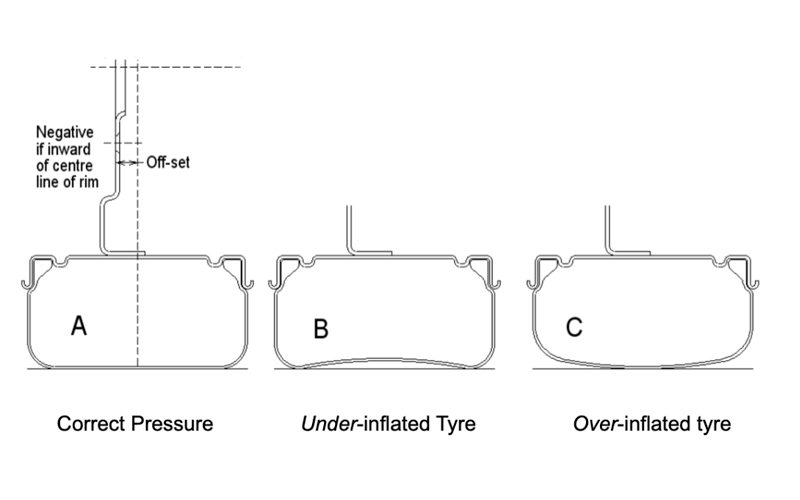

For non-load-sharing suspension systems (on tandem-axle vans), the front and rear tyres will have different loadings, if the van is not level (in a side view). For maximum traction and tread life, the loading needs to be spread evenly across the full width of the tread. This can only be achieved if the correct inflation pressure is used, so that the tread is at the same temperature across its full width. The use of a tyre pyrometer is really the only efficient way of checking this.

INCORRECT TYRE PRESSURES

Under-inflation

If a tyre is not inflated to the pressure that is required to match the actual tyre loading, the tyre tread will not have full contact with the road surface, causing the outer portions of the tread to be subjected to increased loading, with subsequent increased temperatures and increased wear. The traction between the tyre and the road surface will be decreased, and the sidewalls of the tyre will significantly flex, causing the van to wallow and sway.

Over-inflation

Over-inflation

If a tyre is inflated above the pressure that is required to match the actual tyre loading, again the tyre tread will not have full contact with the road surface, this time causing the centre portion of the tread to be subjected to increased loading, with subsequent increased temperatures and increased wear. Again, the traction between the tyre and the road surface will be decreased, causing the tyre to bulge, and the van to bounce and skip.

In both cases, the handling and stability of the van will be impaired, and the tyre life appreciably reduced. While most of the tread will have plenty of kilometres of travel remaining, the outer peripheries of an under-inflated tyre will be worn down to the tread wear indicators, thus rendering the tyre un-roadworthy, while for an over-inflated tyre, the inner periphery will be worn down to a dangerous and illegal level.

WHEEL STUDS AND LOOSE NUTS

According to Colin Young of the Caravan Council of Australia, this organisation has received multiple reports of broken wheel studs and loose wheel nuts. “It must be stressed that if a stud breaks, it is certainly no proof that the stud itself was faulty,” Mr Young said. He said there were a number of potential reasons for these issues. “All supplied instructions regarding wheels and wheel nuts must be precisely followed. It is vital to ensure that if van owners or dealers fit aftermarket wheels and nuts, they thoroughly check to ensure the replacement wheels and nuts are, in fact, completely suitable for the vehicle and axles.”

Mr Young, an engineer, offered the following as possible reasons for broken wheel studs or loose/lost wheel nuts…

• The pitch circle of the studs in the (imperial) hub aren’t exactly the same as that of the holes in some (metric) wheels, such that all studs bend when the nuts are tightened;

• The angle of the taper on the nuts is not the same as the angle of taper in the wheels;

• Low-grade steel studs have been used;

• The hole in the wheel centre is not compatible with the spigot diameter of the hub;

• The serrated studs have not been “fully driven home” when pressed into the hubs, such that they gradually “give a little”, thus causing the nuts to become loose;

• ‘Rattle-guns’ set at unknown high-torque levels have been used to tighten wheel nuts (rather than just undo them, causing the studs to stretch and thus become weakened;

• Nuts being tightened in a circular pattern in one action, rather than in a criss-cross pattern, using two or three (increasing) torques; and

• Wheel centres being highly dished, thus acting as a large spring-washer that gradually looses its tension and causes the nuts to loosen.

“Clearly, all nuts must be tightened to the correct torque, and in the correct pattern, in strict accordance with the instructions provided by the wheel or chassis manufacturer,” Mr Young said. “It is strongly recommended that pencil lines are made on one face of each nut, with a mating line on the wheel, so that a quick visual inspection can detect any loosening of a nut. Clip-on plastic ‘indicators’ – fitted to each nut, with their adjacent ‘arrowheads’ aligned – provide an even-quicker warning of any nut loosening.”

Continual vibrations – and occasional heavy impacts – from road surfaces, would inevitably have an adverse effect on the wheel assemblies, Mr Young said. “This is severely aggravated if the tyre pressures – and the spring rates – are too high for the actual wheel-loading.” Stresses on the wheel assemblies are further increased if shock-absorbers (dampers) are not fitted.

Leaf-springs do provide some damping of vibrations, but unfortunately it is mainly on the “bump” (up-wards) movement of the wheel, rather than on the “rebound” (downwards) movement of the wheel… where it would be far more beneficial.